Products

Vacuum Hose

Brake booster is an enhanced master cylinder setup used to reduce the amount of pedal pressure needed for braking. It employs a booster set up to act with the master cylinder to give higher hydraulic pressure to the brakes and/or lower force applied on the brake pedal. The brake booster usually uses vacuum from the engine intake to boost the force applied by the pedal on to the master cylinder. The main function of Vacuum Hose Assy. is to provide passage for vacuum pressure transmitting from the engine to the master cylinder.

Chemtube’s vacuum hose is made of high performance Nylon PA6, PA11 or PA12 materials. The hose consists of single layer nylon hose, thermoformed to design intend shape with check valve at one end and a fitting at the other end. The hose diameter, shape and end connection can

be customized to meet customer’s requirement.

Operating Condition

- Maximum pressure up to 10 bars

- Pull off force up to 1KN

- Temperature 140 degree C peak. However, special high temperature grade material is available for higher temperature requirement

Chemtube’s Nylon Vacuum Hose Delivers

- Light in weight

- Excellent mechanical properties

- Long-term aging and durability

- Easy to form to shape without heavy duty machine

- Flexibility

- Good resistance to zinc chloride, acids, ozone and other chemicals

- Good impact resistance and high fatique strength

VACUUM HOSE

Vacuum Hose

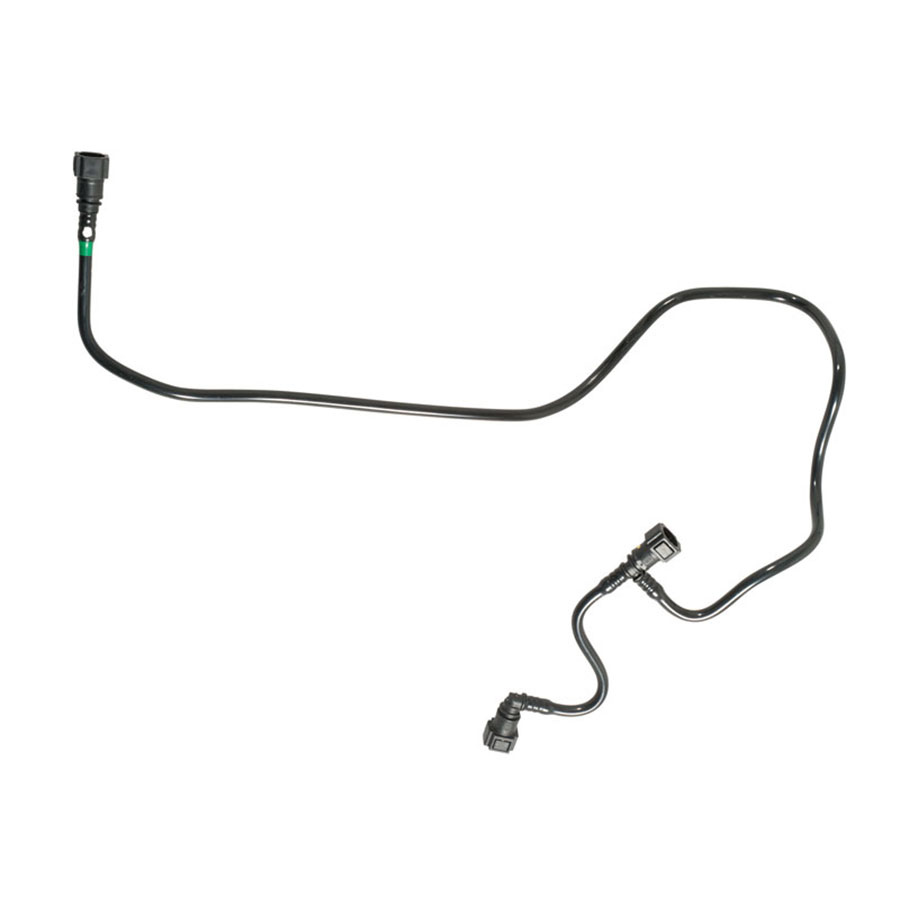

Fuel Tube Assemblies

A fuel line is a hose used to bring fuel from one point in a vehicle to another or from fuel storage tank to engine inlet. Fuel lines are designed to contain liquid fuel or fuel vapor. This includes all hoses or tubing for the filler neck, for connections between under floor piping, and for connecting a carbon canister to the fuel tank.

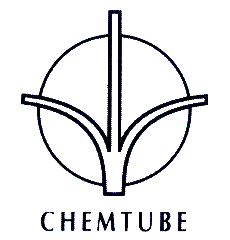

The fuel tube is made of high performance nylon material with end quick connectors fitted at both ends. The construction of the fuel tubes material consists of the following types:

Monolayer Fuel Lines

Single layer wall nylon tube with good chemical and mechanical properties. Common used materials are PA11 or PA12. Suitable for fuel lines with medium permeation requirement.

We also produce fuel lines with different raw material grades which are requested by our customers. *

Multilayer Fuel Lines

A unique 2 or 3 layers wall thickness tube developed with European technology delivering exceptional toughness and corrosion resistance. Suitable for fuel lines system with low permeation requirements and fuel with ethanol.

Specification

| COLD IMPACT TEST | SAE (-40°C/454g) | VW (-40°C/500g) | VW (-40°C/800g) | |

| EMS-EVX 306 | No Break | No Break | No Break | |

| AFTER AGING | SOURGAS PN90/40°C/1000h | DIN 73378 (23°C) | HEAT AGING 150°C/200h(23°C) | |

| EMS-EVX 306 | No Break | No Break | No Break | |

| ELONGATION @ BREAK | ORIGINAL (100mm/min) | CROSS (25mm/min) | SAE (50mm/min) | |

| EMS-EVX 306 | No Break | No Break | No Break | |

| PERMEATION TEST | SAE 1737 60°C/2bar/CM 15(g/day*m²) | |||

| EMS-EVX 306 | 80 | |||

The end fitting design can be in:

a. Quick connector or spool

b. Metal coupling or adaptors

c. End beads (connected with short rubber hose with constant pressure clips) – for vapor lines only

Operating Condition

- Working pressure up to 20 bars

- Burst pressure up to 60 bars

- Pull off force up to 250N

- Temperature 140 degree C peak. However, special high temperature grade material is available for higher temperature requirement.

Chemtube Fuel Lines Provide

- Medium to low permeation rating with high performance barrier properties

- Good chemical resistance

- Excellent mechanical properties

- Long-term aging and durability

- Flexibility

- Good impact strength at low temperature

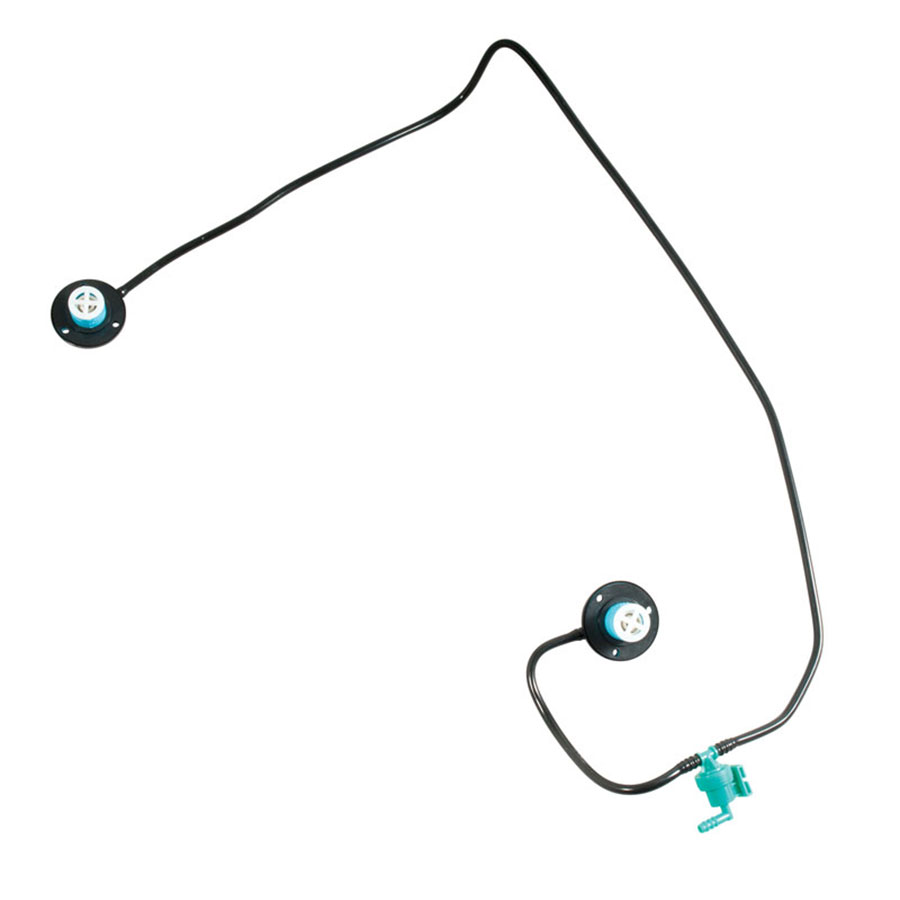

Fuel Tube Assy-Roll Over Valve

Fuel Tube Assy-Tube Return

Fuel Tube Assy-Tube Main

Fuel Tube Assy-Tube Feed

Fuel Tube Assy-Pipe Assy Drain

Fuel Tube Assy-Tube Purge

Corrugated Fuel Lines (Fuel Filler)

Made of advanced high precision corrugation technology with choice of monolayer or multilayer constructions. Suitable for fuel filler hose and breather hose application. Corrugated hose length and shape can be customized to suit customer’s requirement.

EVX 306-Corrugated Fuel Lines-Tube Leveling

EVX 306-Corrugated Fuel Lines-Tube Filler

EVX 306-Corrugated Fuel Lines-Tube Filler

Leveling Corrugator Hose

Filler Corrugated Hose

Corrugated Fuel Lines-Neck Assy Filler

Clutch Tubes

Clutch system is used in vehicles with manual transmission. Clutch acts as a coupling device to separate the engine and transmission during gear changing or stagnant condition. The clutch tube carries hydraulic oil and provides the link between clutch master cylinder and engine transmission.

Chemtube’s single layer clutch tube is made of high durability Nylon PA12 material, thermoformed to intended design shape with overmoulded connector with O-ring at both ends. The hose diameter, thickness, shape and end connection can be customized to suit customer’s requirement.

The end fitting design can be in:

a. Overmoulded end connector with o-ring

b. Metal adaptor (optional)

Operating Condition

- Maximum pressure up to 65 bars

- Pull off force up to 1KN

- Temperature 140 degree C peak.

Chemtube’s Nylon Clutch Hose Delivers

- Excellent mechanical properties

- Long-term aging and durability

- Easy to form to shape without heavy duty machine

- Flexibility

- Good resistance to zinc chloride, acids, ozone and other chemicals

- Good impact resistance and high fatigue strength

8X3.5-PA12

8X3.5-PA12-B01

Overmould Connector Clutch Tube with Brass Adaptor

Clutch Tube with Brass Adaptor

Thermo-Shrink Tube

Chemtube’s Polyolefin Thermo Shrink Tubes with an inner layer of glue are cross-linked with Electron Beams.

Application

Used for mechanical or corrosion protection of metal pipes such as power steering, fuel lines and brake lines. It is also commonly used in cable hardness.

Advantage

- Provide good corrosion protection and resistance

- Excellent mechanical & abrasive protection

Air Brake Tube

They can be used in a wide range of instrumentation and secondary air systems. The tubes provide good resistance against ageing caused by heat and light, and have a wide range of operating temperatures (-40°C to +93°C).